Application&Samples

Applicable industrial: Specially used for cutting 0.5-25mm carbon sheet, 0.5-15mm stainless steel, galvanized steel, electrolytic zinc-cooled steel sheet, silicon steel, 0.5-10mm aluminum, 0.5-8mm brass and red copper and other kinds of thin metal sheets(the thickness and materials depend on different fiber laser source).

Applicable materials: Mainly used for cutting steel, silicon steel, stainless steel, aluminum, titanium, galvanized sheet, stuffed washer, galvanized plates and other metal materials.

| Material |

Carbon steel |

Stainless steel |

Galvanized steel |

Electrolytic zinc-cooled steel sheet, |

Aluminum |

| Szie |

0.5-25mm |

0.5-15mm |

0.5-15mm |

0.5-15mm |

0.5-10mm |

Used in elevators, kitchen utensils, household application, gift, tooling, decoration, advertising, metal external processing thin metal parts manufacturing and processing industries.

Samples

Specification

| Items |

Parameters |

| Working area(L*W) |

3000*1500mm |

| X.Y.Z. axis stroke |

3000mm 1500mm 120mm |

| X/Y position accuracy |

±0.02mm |

| Z position accuracy |

±0.008mm |

| X/Y repeat position accuracy |

±0.015mm |

| Max. speed |

120m/min |

| X/Y max. acceleration |

1.2G |

| Max. loading weight |

1.5t |

| Machine weight |

7t |

| Outer size (L*W*H) |

8200*2900*2300mm |

| Voltage |

380V/50Hz/100A |

| Running temperature |

5-38℃ |

| Continuous working time |

24H |

| Cooling |

Water cooling |

Features

1.Imported electric components

2.Industrial casting aluminum gantry

3.Whole machine CNC assembly

4.High speed welding heavy machine body

5.High speed exchange table

6.Whole machine full protection

FC-3015Q full protection fiber laser cutting machine designed according to European standards, adopts domestic first-class fiber laser (optional), moving gantry structure, the machine uses light weight design, acceleration really achieve 1.2G, high-speed 120 m/min, industrial casting aluminum,the whole machine processed by CNC machining center, 600°high temperature quenching, electrical machines originals are of international brands, 24H processing without worry, good stability and security can be maintained for a long time, standard care with heavy pneumatic feeding devices, thick material processing light fast (and optional automatic pallet, when it cuts while feeding, convenient and save time).

Spart Parts

|

Lathe bed

Name: Lathe bed

Brand: Fanch

Original: China

Weld temper heat treatment

|

|

Crossbeam

Name: Crossbeam

Brand: Fanch

Original: China

Cast aluminum

|

|

CO2 Laser tube

Name: CO2 laser tube

Brand: EFR

Original: China

Chinese top brand laser tubes

|

|

Ball screw

Name: Ball screw rod

Brand: TBI

Original: Taiwan

High specision screw rod.

|

|

Chiller

Name: Laser cutting chiller

Brand: S&A

Original: China

Top brand chinese laser chiller,

it can help to fast cool down the laser cutting machine

make sure 24H continuous work.

|

|

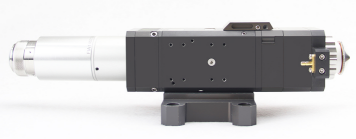

Laser cutting head

Name: Laser cutting head

Brand: RayTools

Original: China

Cutting head: RayTools| BT230,

easy to focus, precision,

the structure is compact and portable,

and matching BCS300 independent high capacitance.

|

|

Helical rack

Name: Helical rack

Brand: FengMao

Original: Taiwan

High accuracy helical rack

|

|

Reducer

Name: Reducer

Brand: NEUGART

Original: Germany

High Running accuracy, running accuracy 1arc

|

|

Electric components

Name: Electric components

Brand: Schneider

Original: French

Taiwan AirTAC is optional.

|

Factory

Woodworking Machine

Located in Tongzhou district, Beijing, Fanch woodworking factory was established in 2006. There are about 100 worker and technicians working in welding, milling and assembly departments.

Laser cutting machine factory

Located in National Innovation Industry Park in Tongzhou, Fanch laser machine assembly department, R&D office and

domestic sales office can be found here.

Our Services

|

|

|

Pre-sale service

1. Free engineer consultant and feedback in 24 hours.

2. Sample specimens and testing video of specified machine are available.

3. Factory visit arrangement.

|

After-sale service

1. Prompt reply in 24 hours.

2. Engineer on-site installation.

3. Call-in Remote diagnosis.

4. Engineer oversea service.

5. Operation training service.

|

Customized service

1. OEM/ODM service are available.

2. Free engineer consultant

3. Engineer on-site installation and debugging.

4. Operation training service

|

Contact Us

Beijing FANCH Machinery Co., Ltd

Beijing FANCH Machinery Co., Ltd

Contact: Mr. Tonboy Tang

Skype: tonboy1314

Mob/Whats App: +86 15600027172

Facebook:fanchcnc/fanch005[at]fanchcnc.com